i.AIM® Product Modules

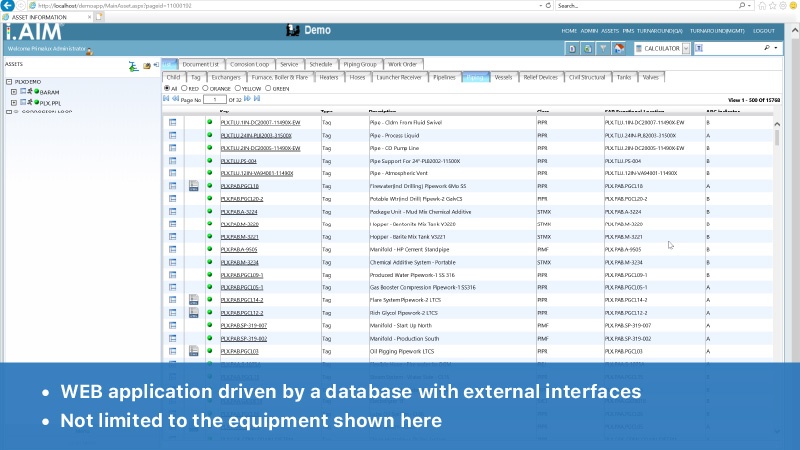

A suite of integrated WEB based modules for Asset Integrity Management.

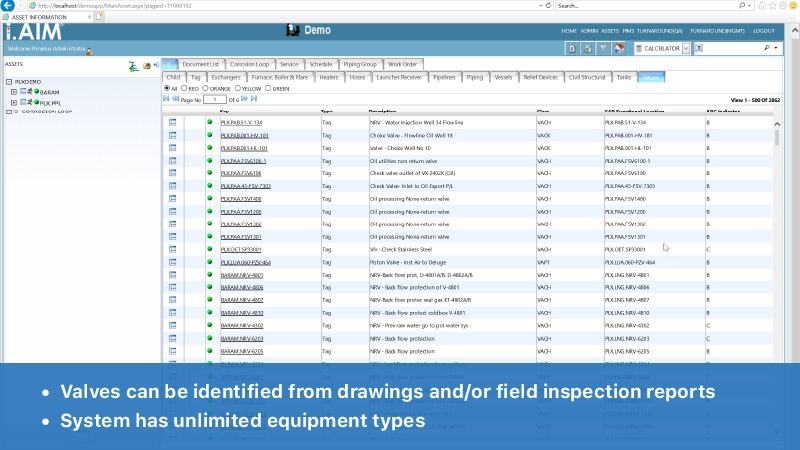

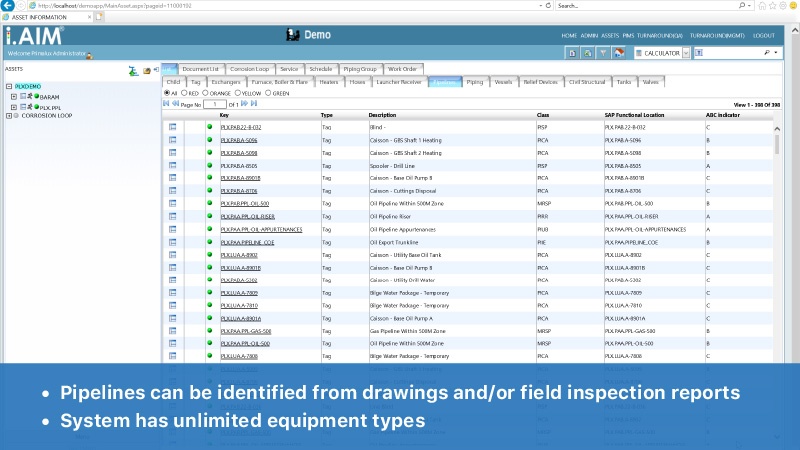

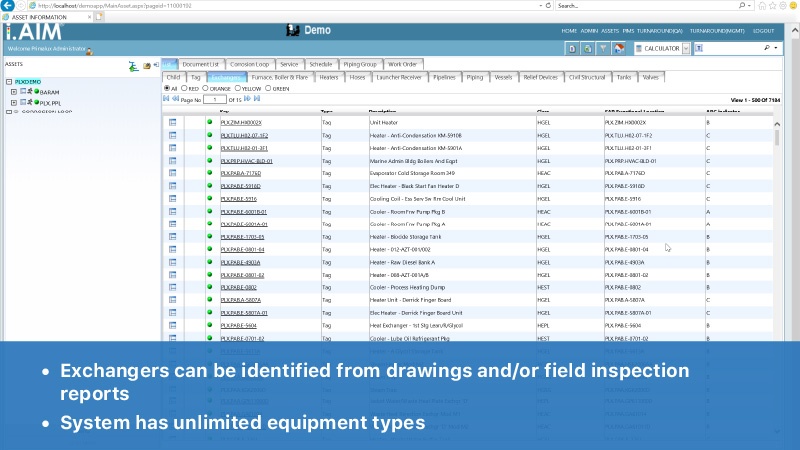

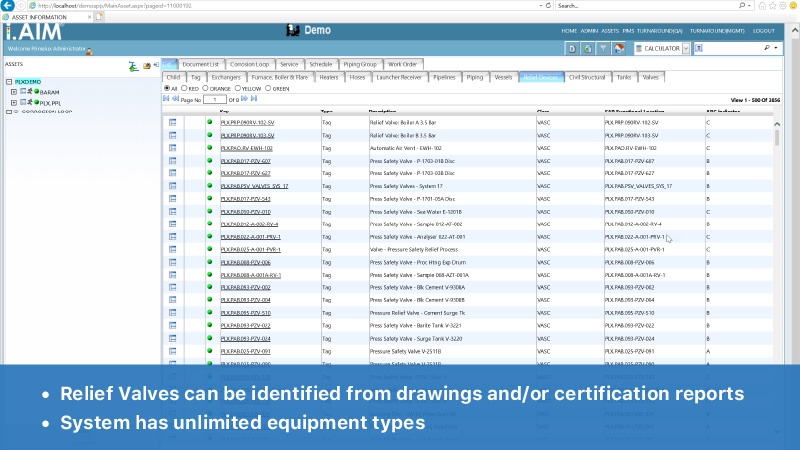

i.ENGINEER is the core module of the entire i.AIM system. i.ENGINEER utilizes a form designer that accommodates different types of equipment and components. It also includes a flexible asset hierarchy system that can cater to different hierarchical data sets, including activities (work) and drawings. This flexibility allows i.AIM to interface with various corporate systems. Work management systems like SAP and PI have different hierarchies, drawing systems, and naming conventions. i.ENGINEER accounts for all these differences and maps them out, making communication possible between the different systems. For example, SAP or PI data can appear on drawings via i.AIM. The activities are important so the integrity-related activities can be easily mapped into a corporate planning tool like Primavera.

Multiple Flexible Asset (Data) Hierarchies

- Production Facility Hierarchies

- Drawing Hierarchies

- Document Hierarchies

- Organization Hierarchies

- Activity Hierarchies (Activity/Project Management)

- Key Performance Indicator Hierarchies (Roll Up Summaries)

- External System Data Hierarchies

Form Designer

- Process Data Forms

- Engineering Specification Forms

- Equipment Profile Forms

- Data Collection Forms

- Risk Management Forms

- Report Format

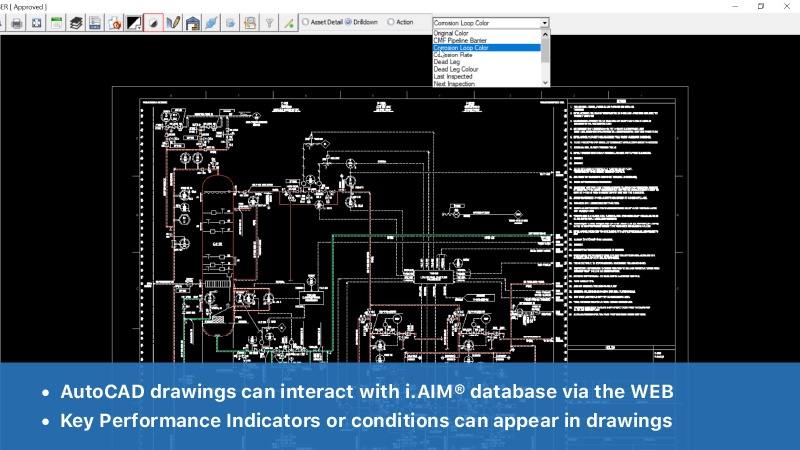

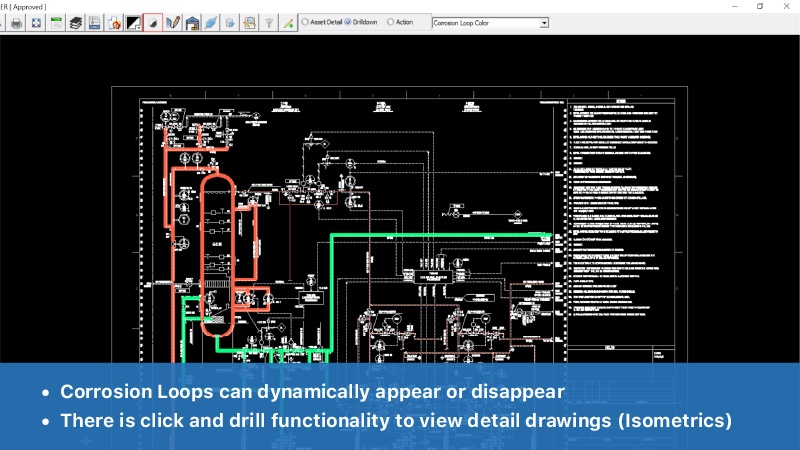

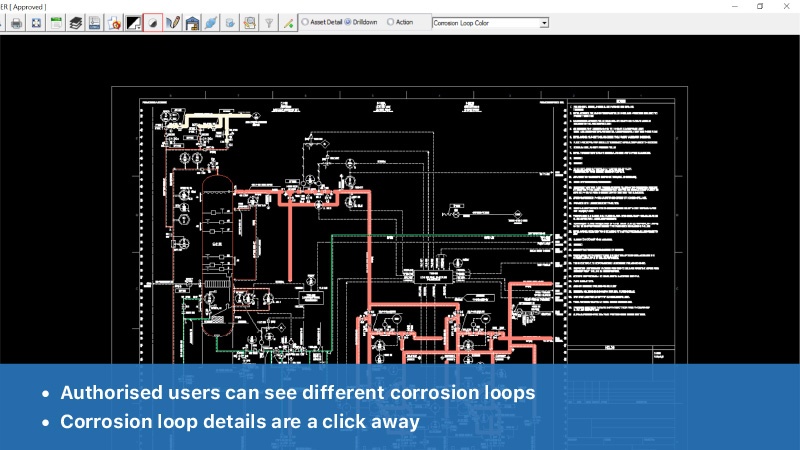

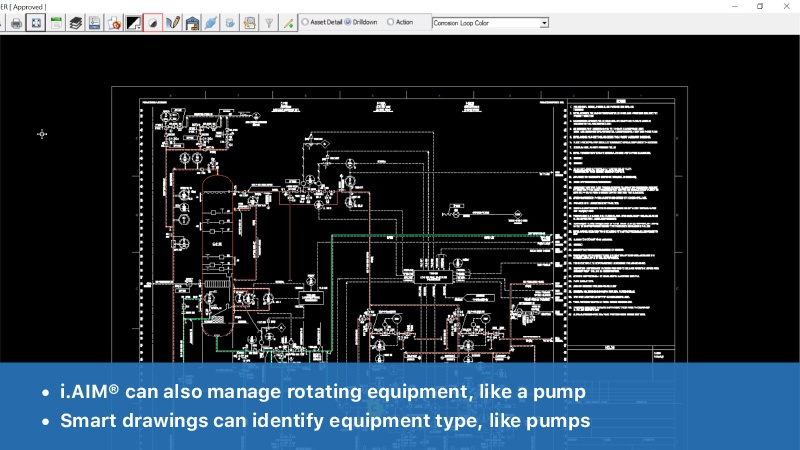

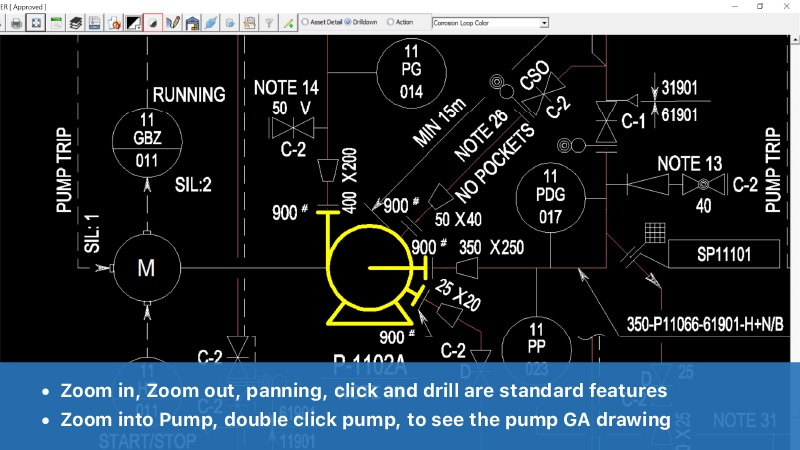

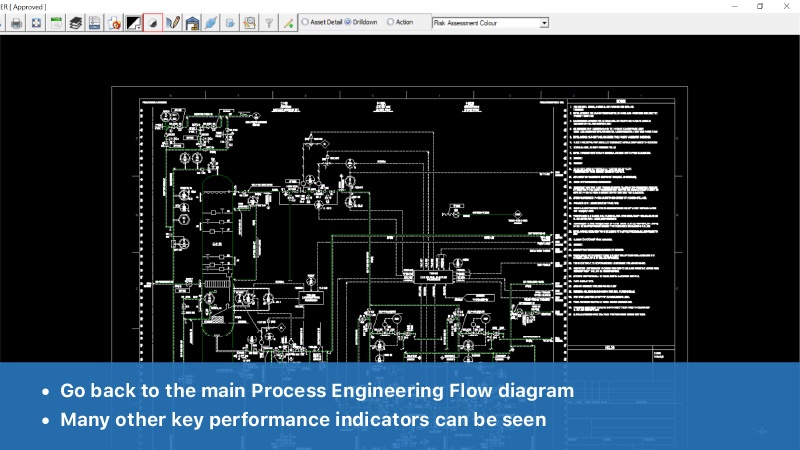

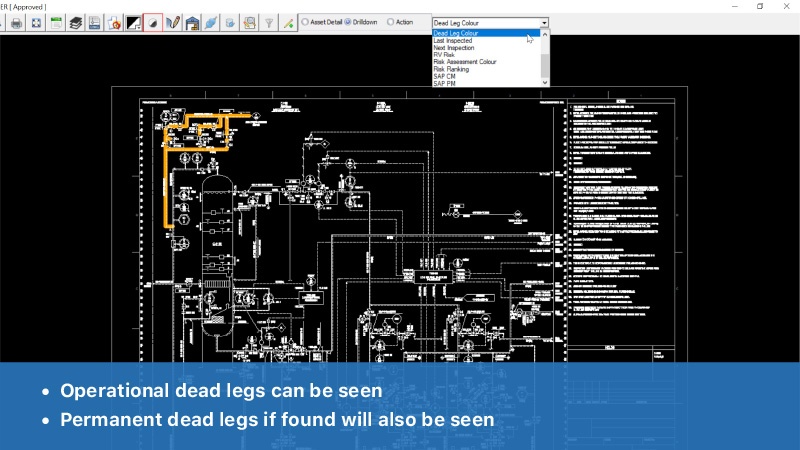

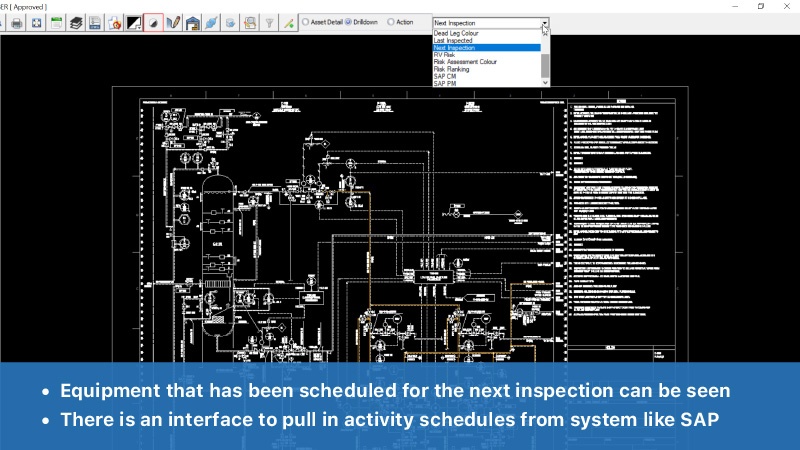

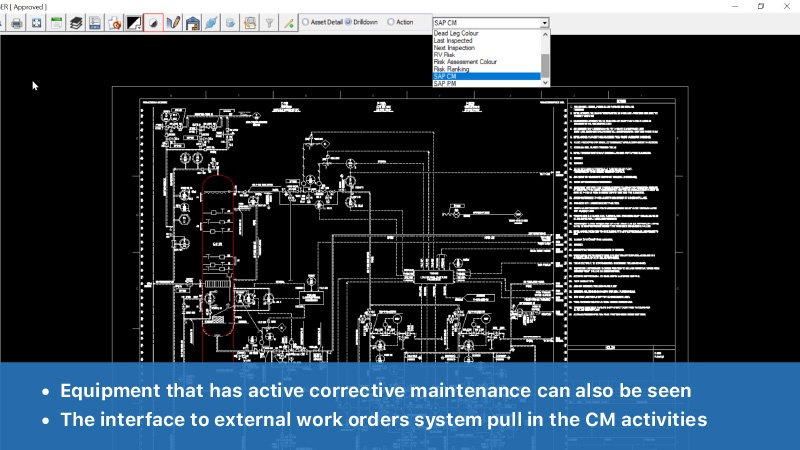

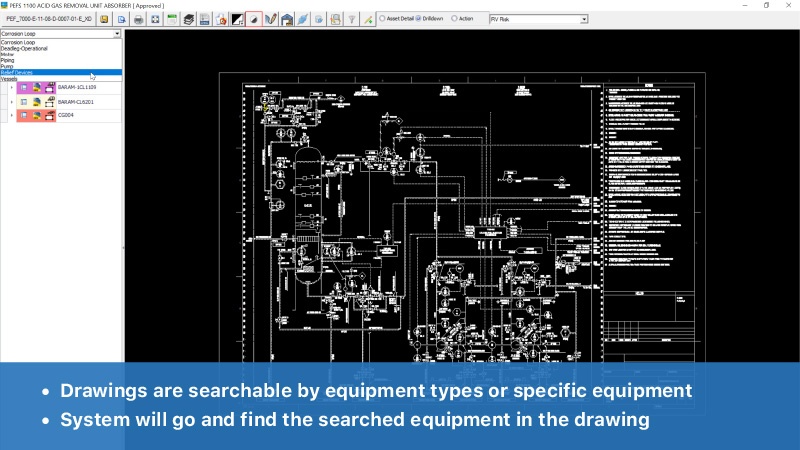

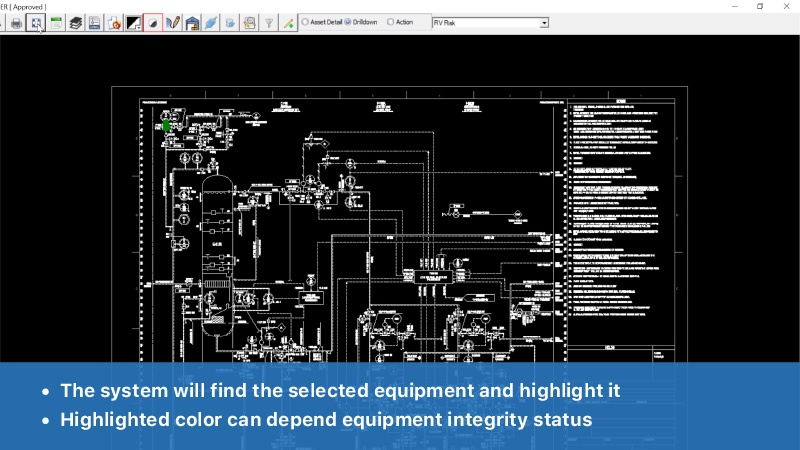

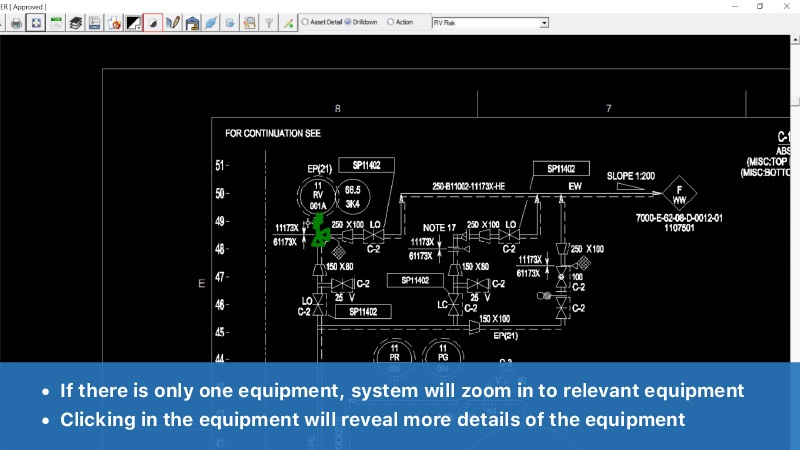

This module enables the smart drawings feature of i.AIM. AutoCAD drawings become interactive with the i.AIM database and interfaced external applications (i.e., SAP, PI, LIMs, ROV Videos…). The objects in the AutoCAD drawing become identifiable objects, and traffic light Key Performance Indicators can appear in the drawing. Corrosion Loops on Process Engineering Drawings become interactive too. The Graphics module also allows for visual display of CP data to determine protection effectiveness. User privileges (roles and responsibility) control what the user can select and view.

Available KPI Views

- Integrity Status

- Corrosion Rates

- Corrosion Loops

- Dead Legs

- Preventative Maintenance Schedules

- Corrective Maintenance Status

- Integrity Operating Window Compliance

- Corrosion Barrier Effectiveness

- Turnaround Campaign Scope

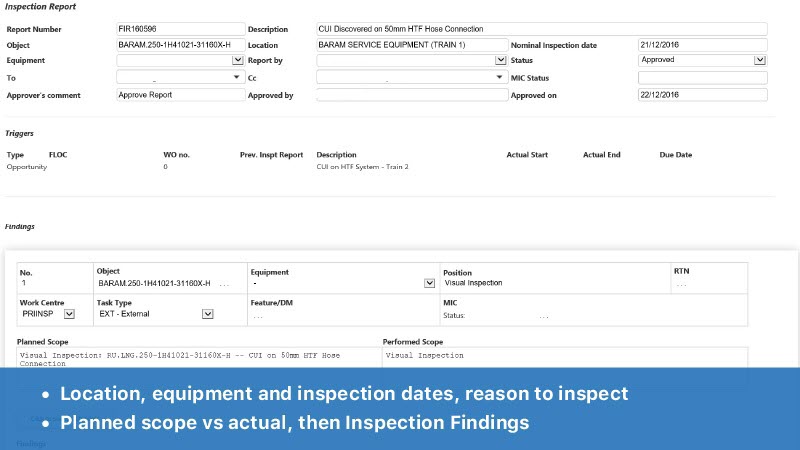

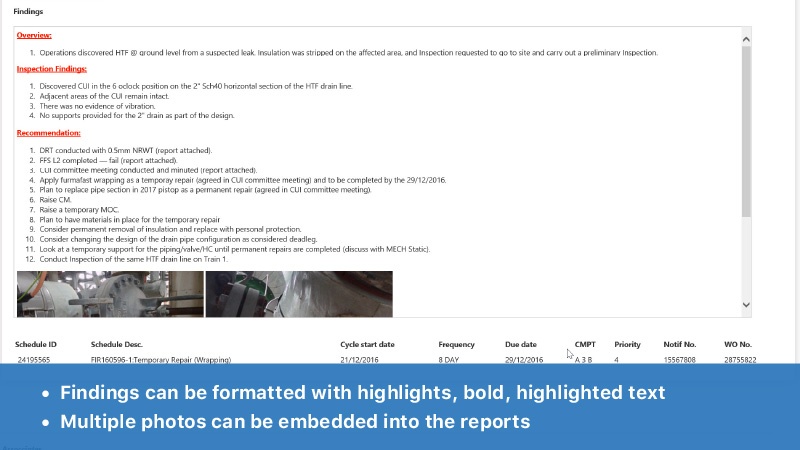

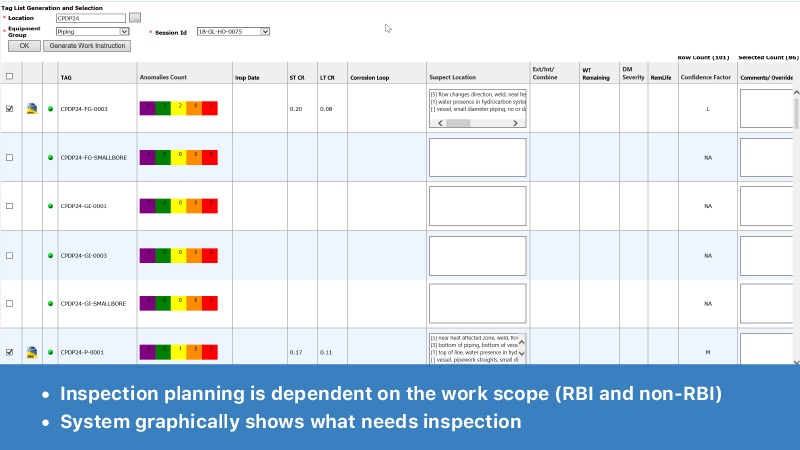

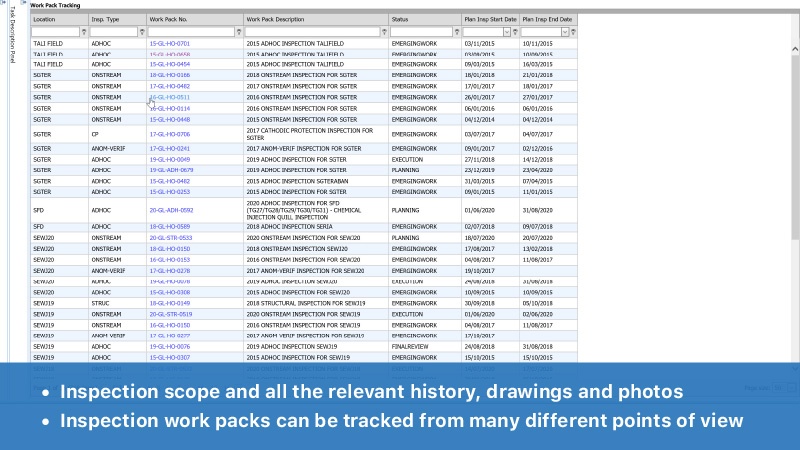

This is the inspection management module of i.AIM. Inspectors can prepare the required work scope and inspection work packs via the inspection planning tool, which includes history, photos, and drawings. The system will track the progress of the work pack from creation through execution to final completion and any recommendations. The recommendations can be interfaced to work order management systems like SAP. Inspection Reports consist of scope, findings, and recommendations. Besides text, it also accepts multiple photographs and detailed readings from the respective inspection tools. The interface to the inspection tools can be two-way, and when appropriate, the inspection scope can be loaded into the data loggers. A simplified tablet version of this module is also available on Android and iOS that can work online and offline.

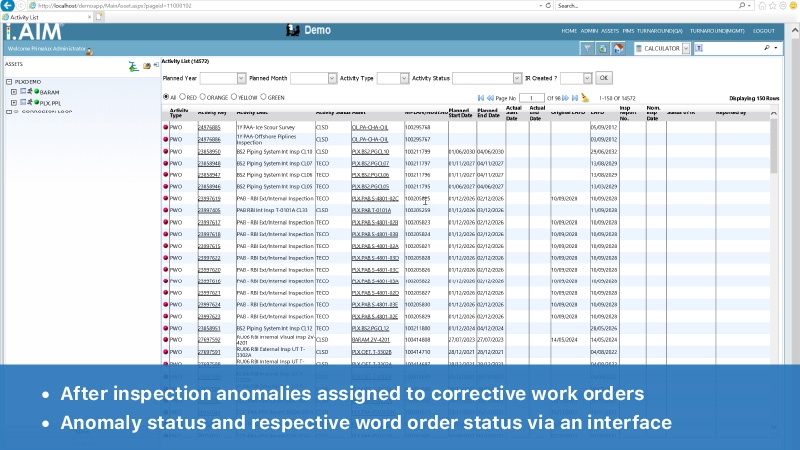

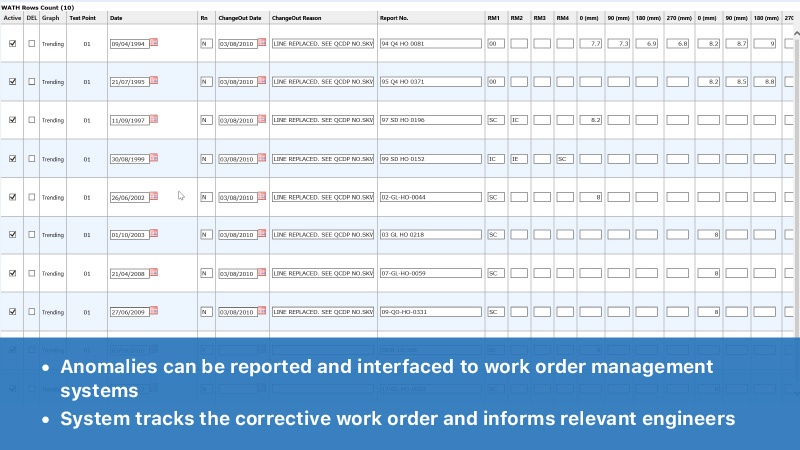

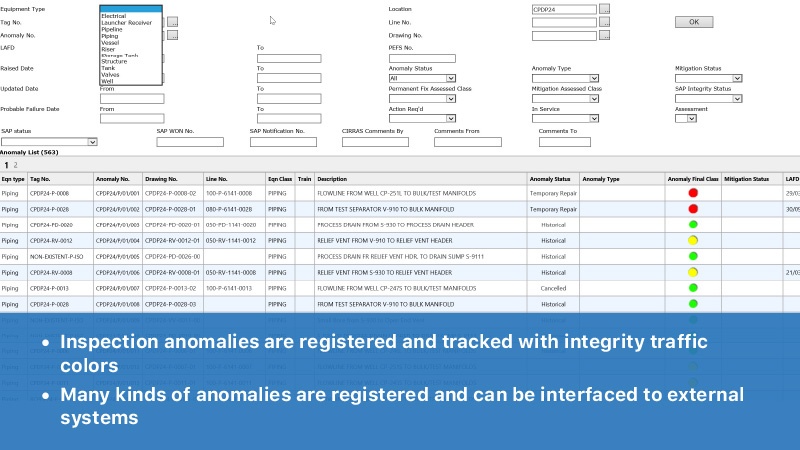

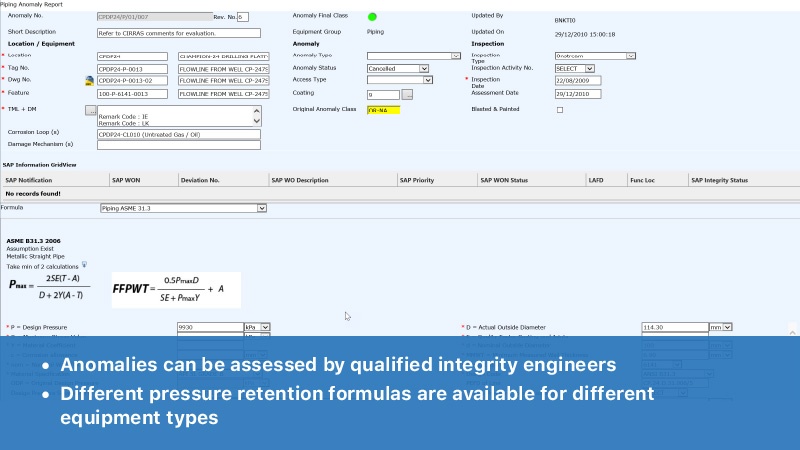

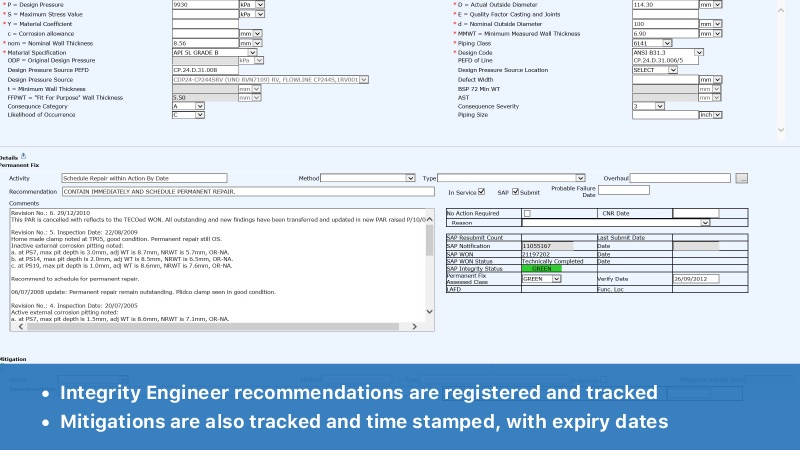

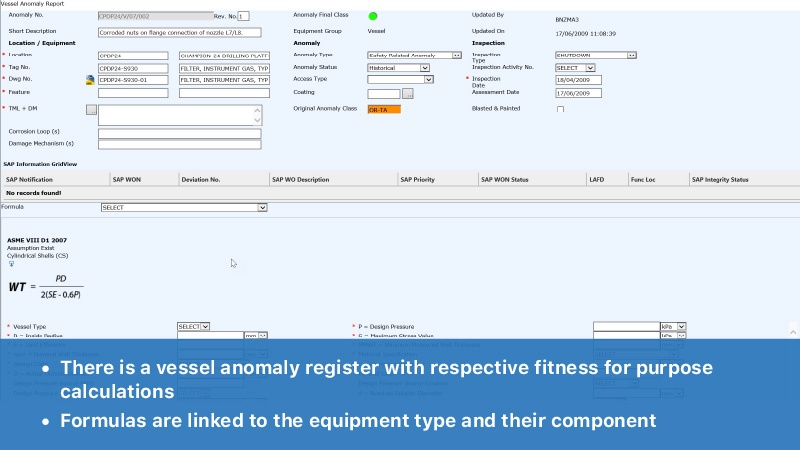

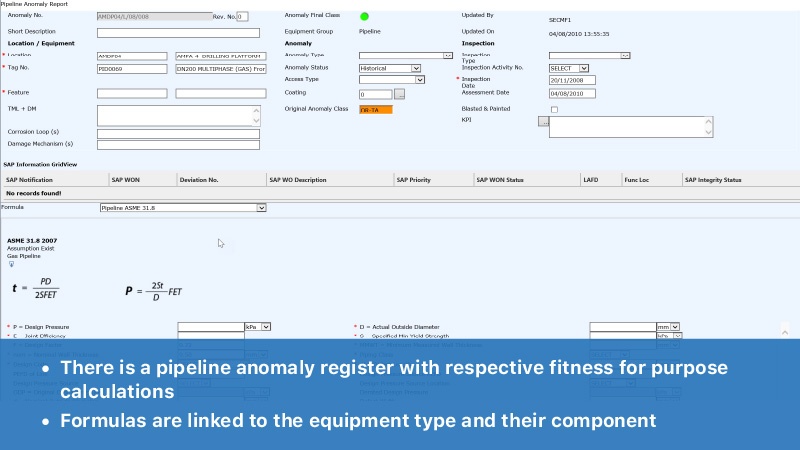

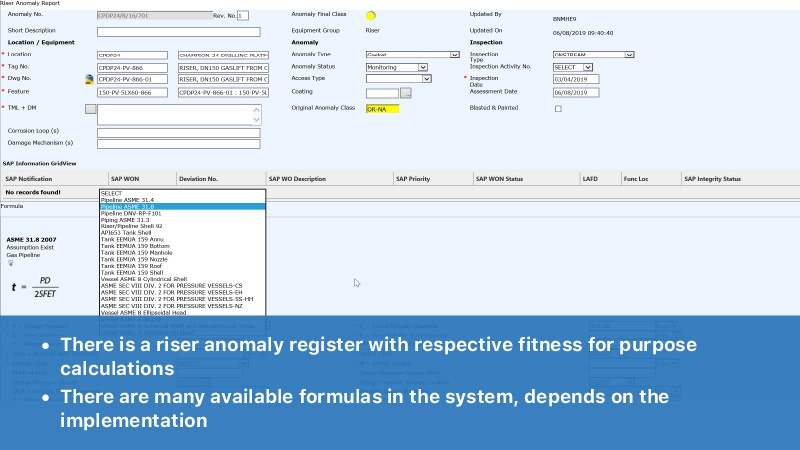

Anomaly Management

- Anomalies found during operations or shutdowns are registered in the anomaly module

- Anomalies are assessed and ranked by traffic light color

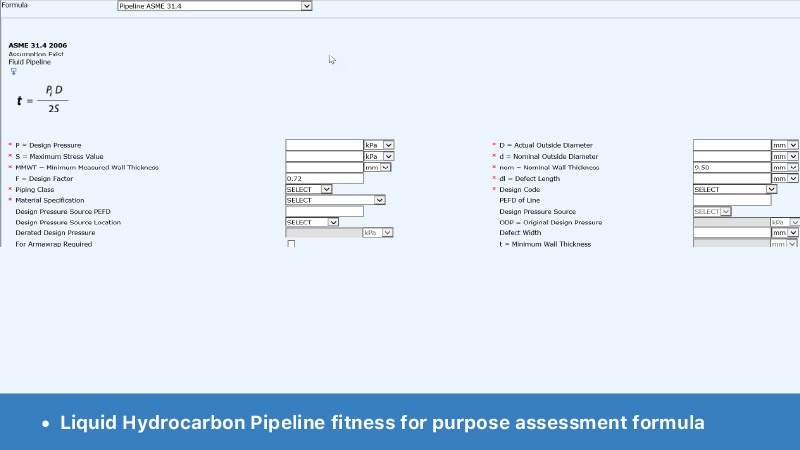

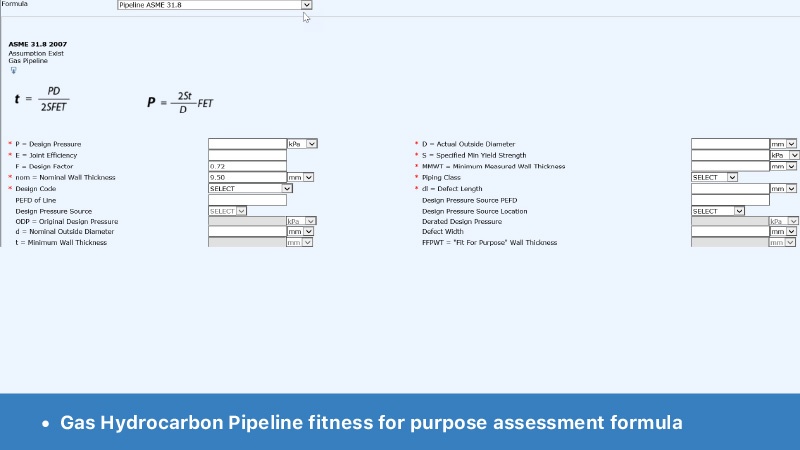

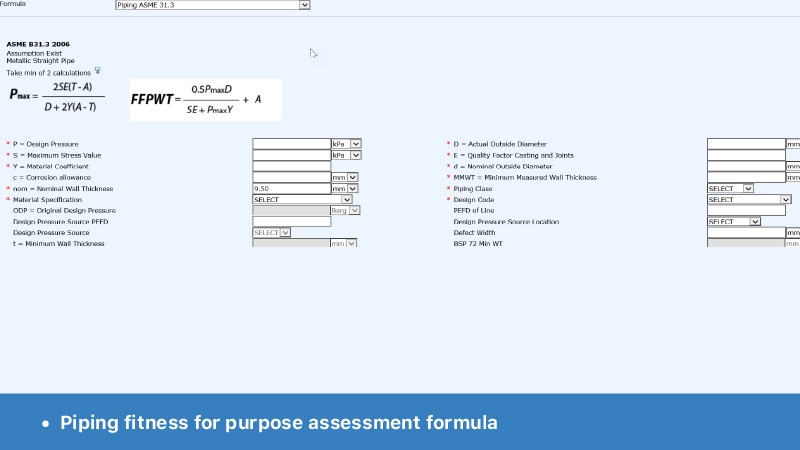

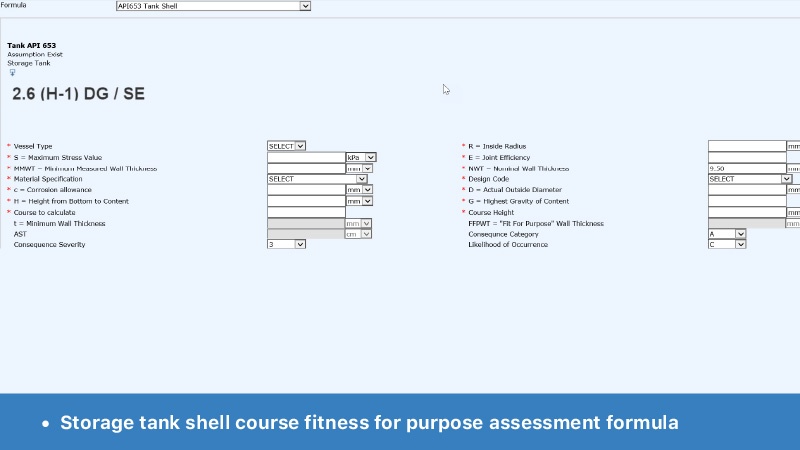

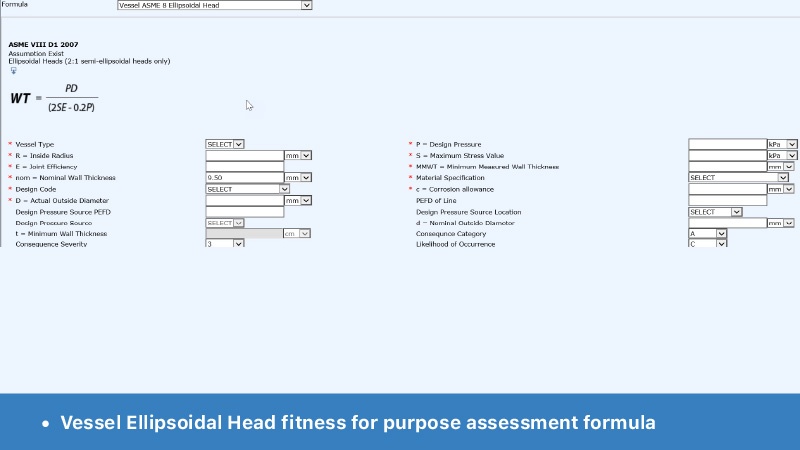

- FFP and FFS formulas are incorporated into the anomaly module

- Tracks dates of mitigations, expiry dates and action by dates

- If interfaced to Maintenance Management System it also tracks work order compliance dates, including cancelled work orders

- Can also be combined with Performance Standards Quality Management System

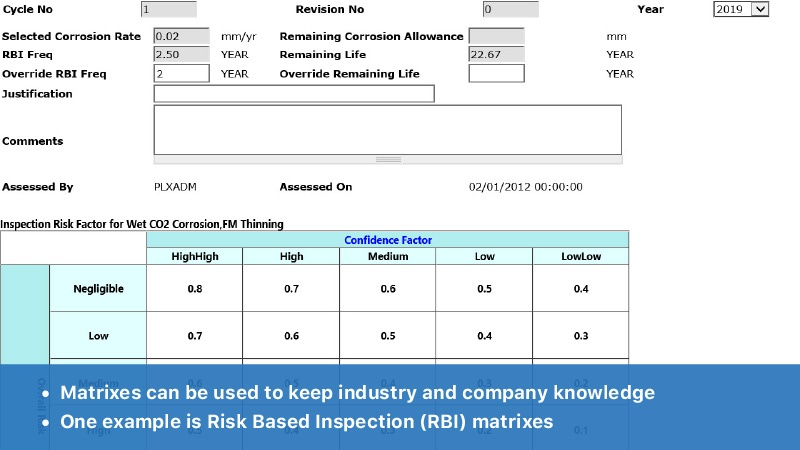

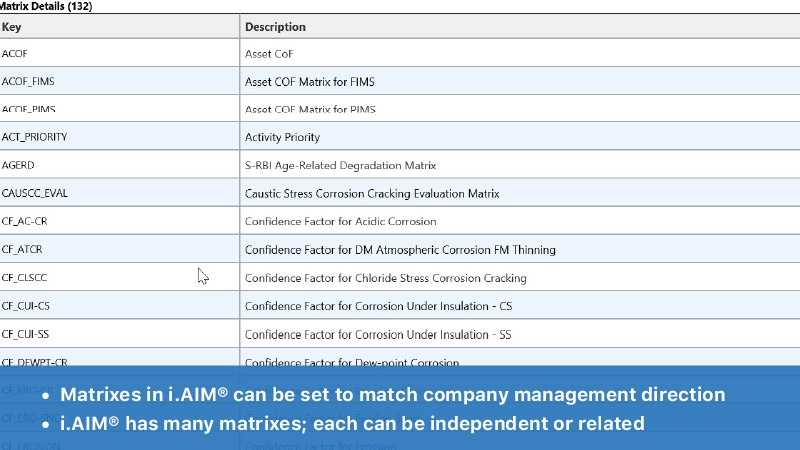

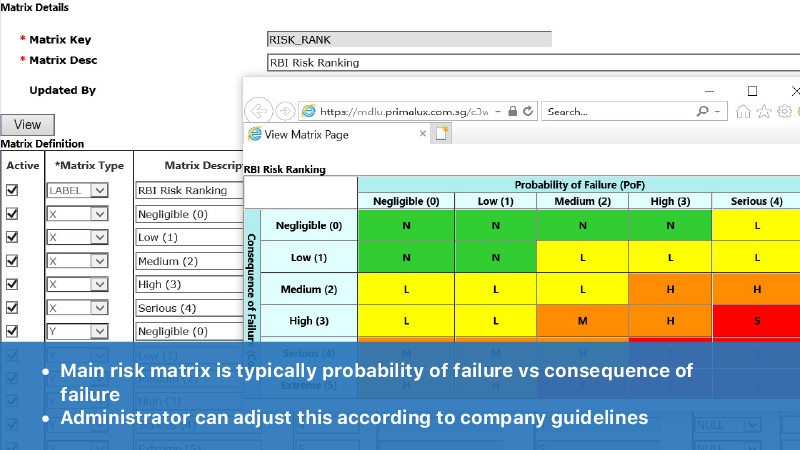

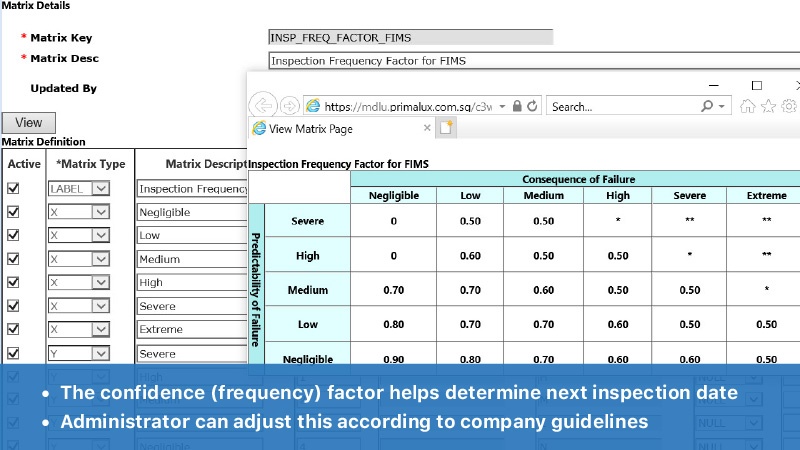

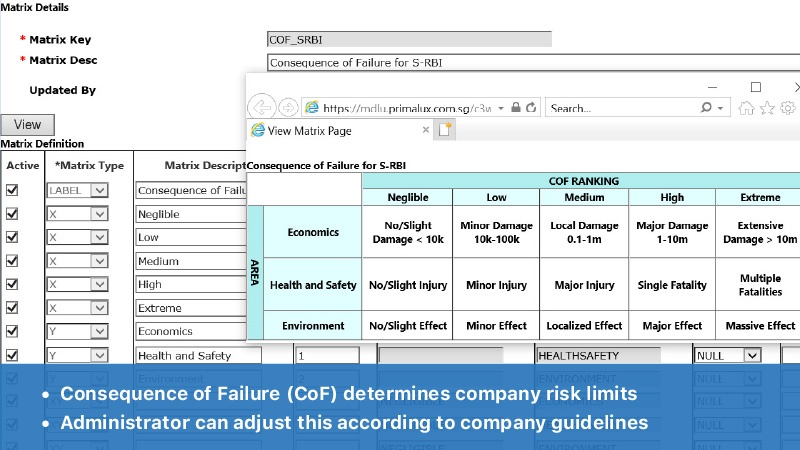

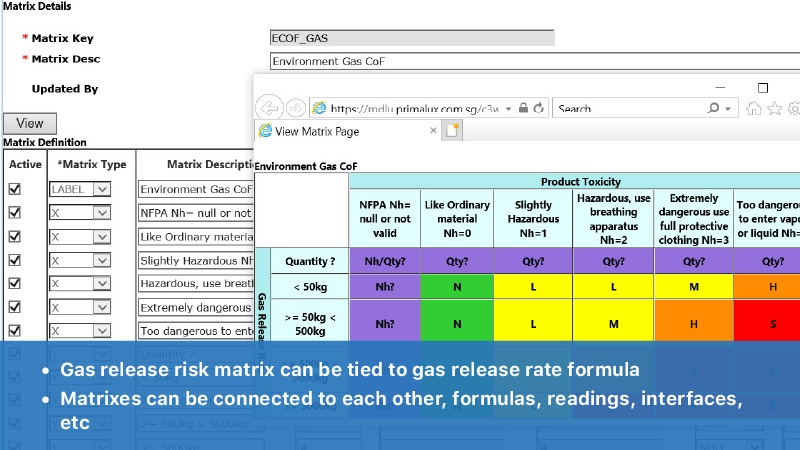

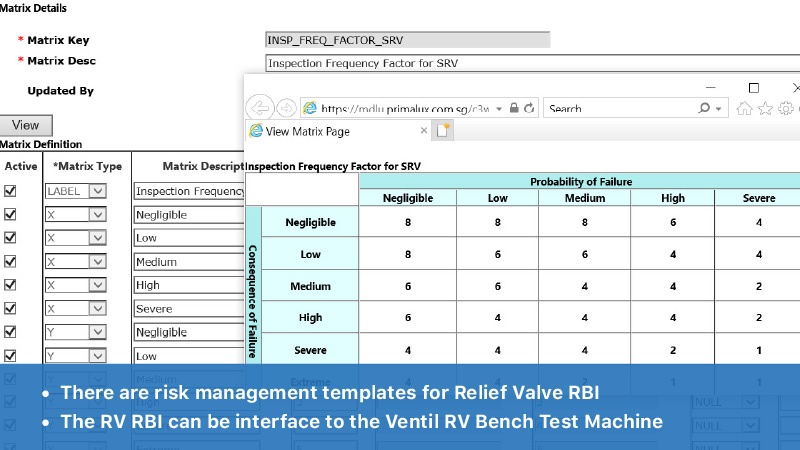

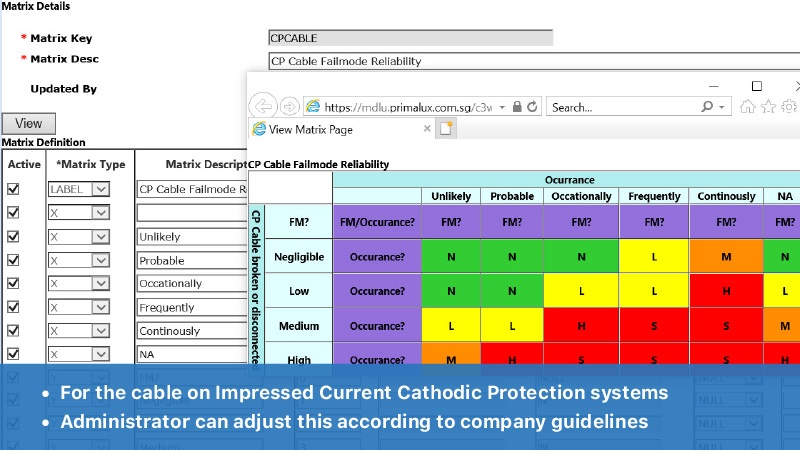

This is the risk management module of i.AIM. It consists of risk management decision matrixes that are configurable. The current methodology of risk management is based on the consequence of failure (CoF) and the probability of failure (PoF) combined with the duration of risk exposure. There are many risk matrixes that are linked to the main risk management matrix because different failure modes and failure threats (damage mechanisms) have different methods of assessment in terms of PoF. Ideally, the CoF needs to be consistent across the company so that risk levels can be compared and priorities and procedures set accordingly. Government and management attitudes towards risk management differ between countries and companies; as such, the risk matrixes need to be flexible and adjustable for different risk management regulations, rules, and procedures. Cultural and technological advances may also affect the acceptance of risk; thus, the risk model will have to change to reflect the new ideology.

Burst Curve

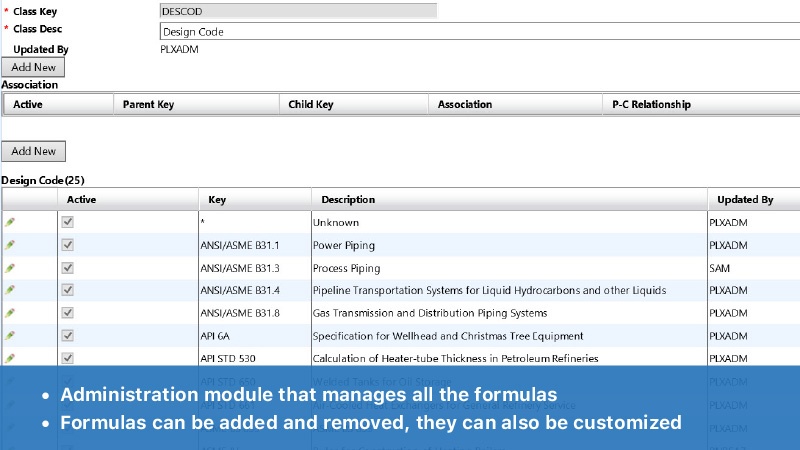

Besides the specific forms needed to collect the analyst data from the core i.ENGINEER module, this module is also the formula creation module. The formula will define the variables required to be placed into the forms. Essentially, all of the formulas are defined in this module (pressure retention piping, pipeline, vessels, or corrosion rate formulas; gas or liquid release rate formulas; financial loss formulas, etc.). The forms needed for the input and output are created in i.ENGINEER. Formulas can also be linked to decision matrixes and data hierarchies for roll-up or push-down summaries and calculations.

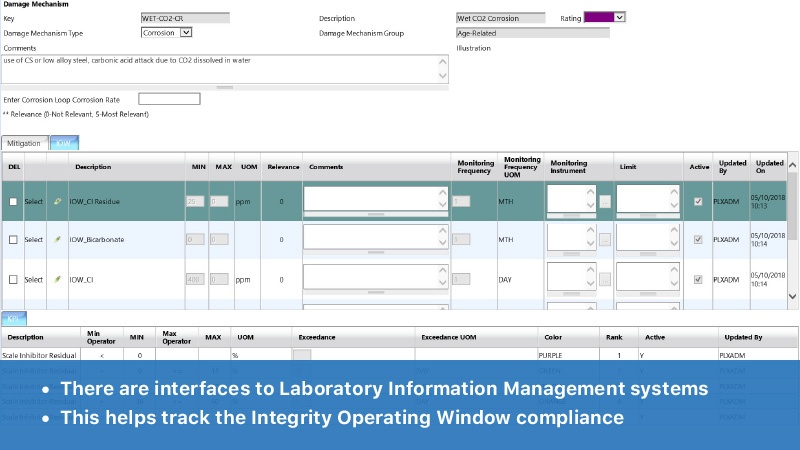

Corrosion Management Module

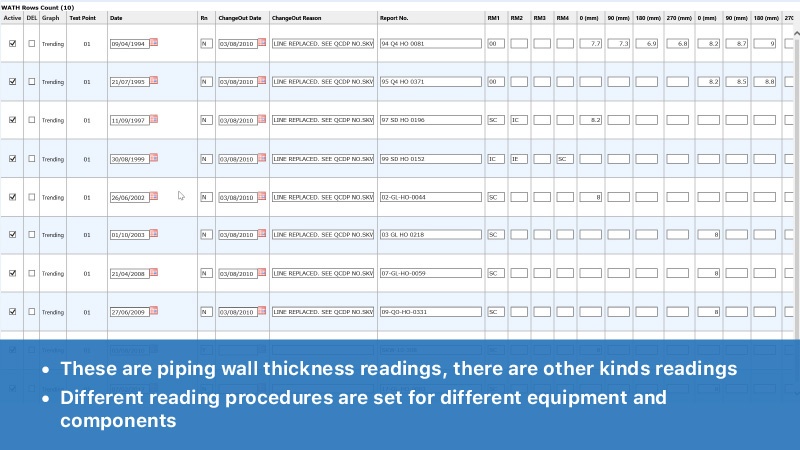

- Corrosion Monitoring Readings

- Corrosion rates for all components

- PI and LIMS interfaces

- IOW management

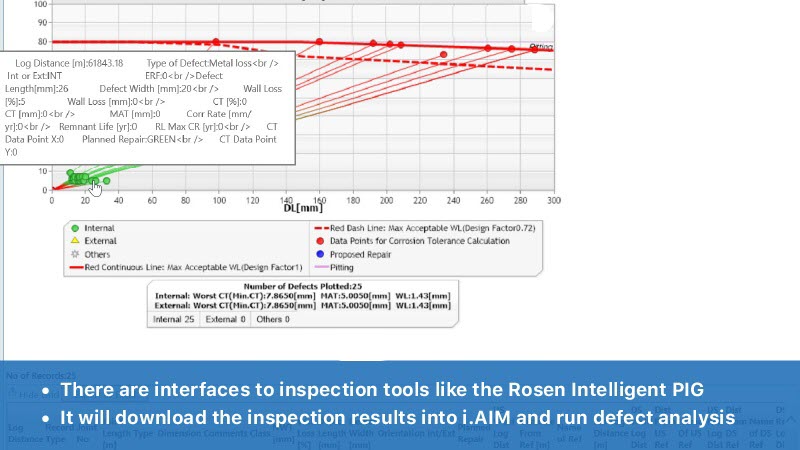

Pipeline Damage Pattern Detection

i.AIM® provides detailed information regarding pipeline defect geometry.

- Clock position, kilometer mark, defect depth, length and width

Both internal and external defects can be seen via a graphical interface.

- Allows pipeline engineers to graphically see how the defects are lining up

- Attachments to the pipeline are also shown on the graphical interface

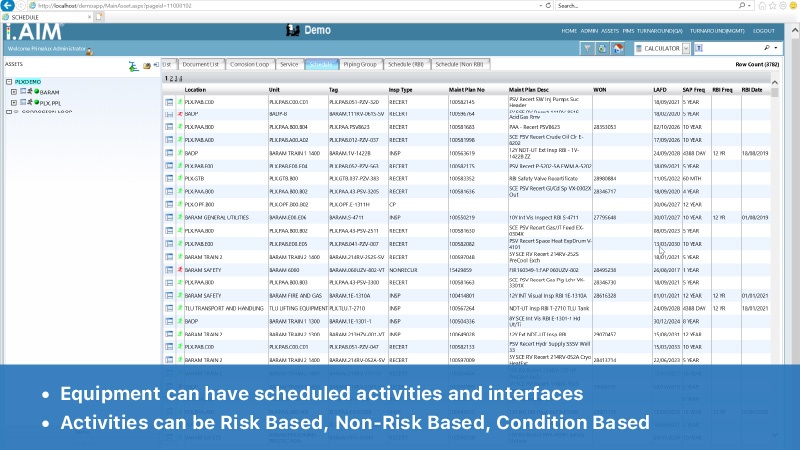

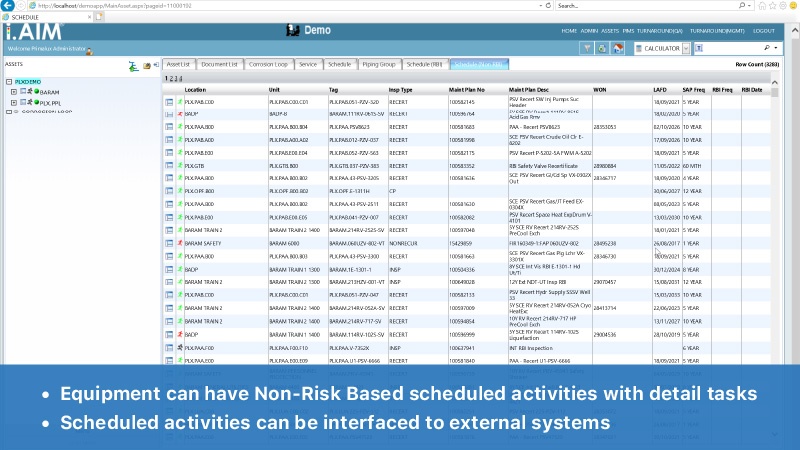

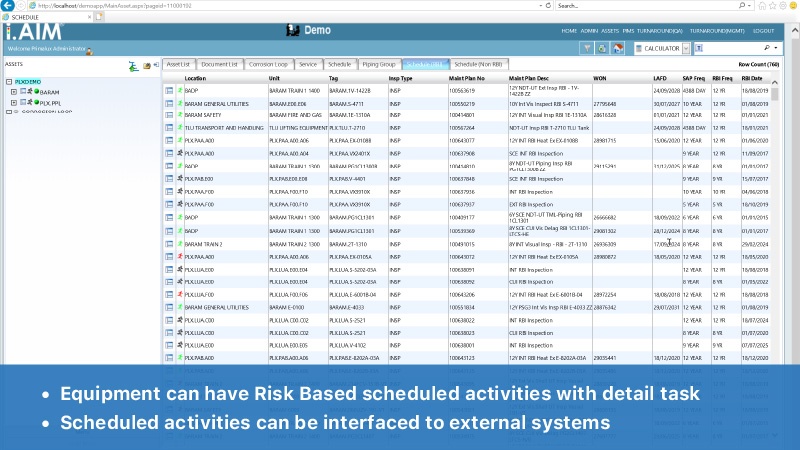

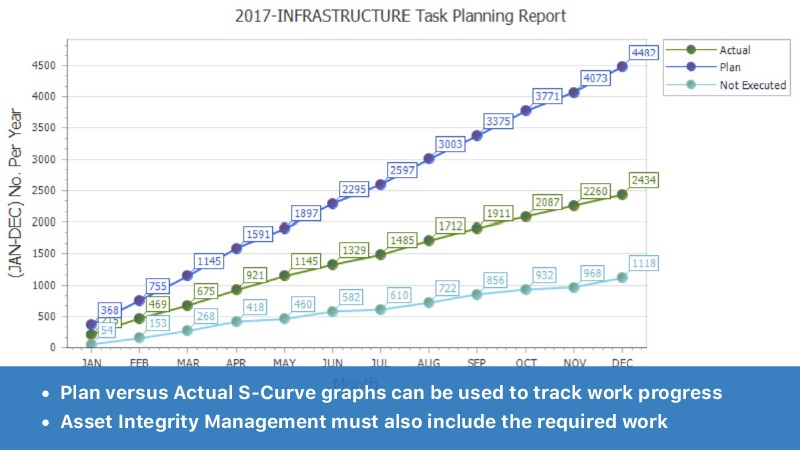

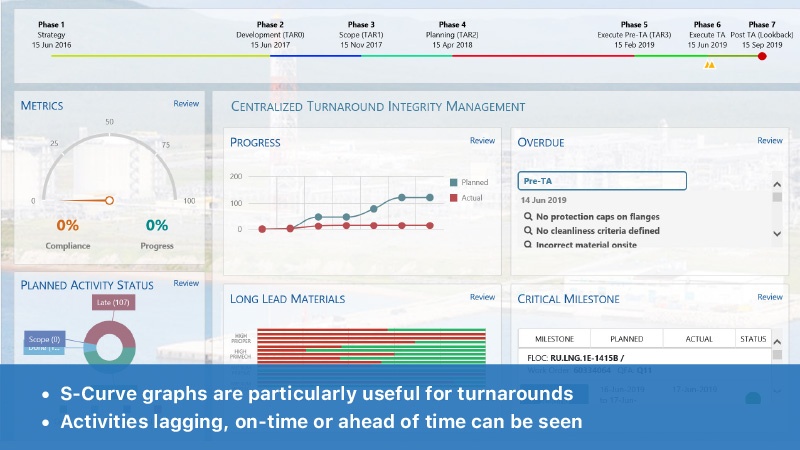

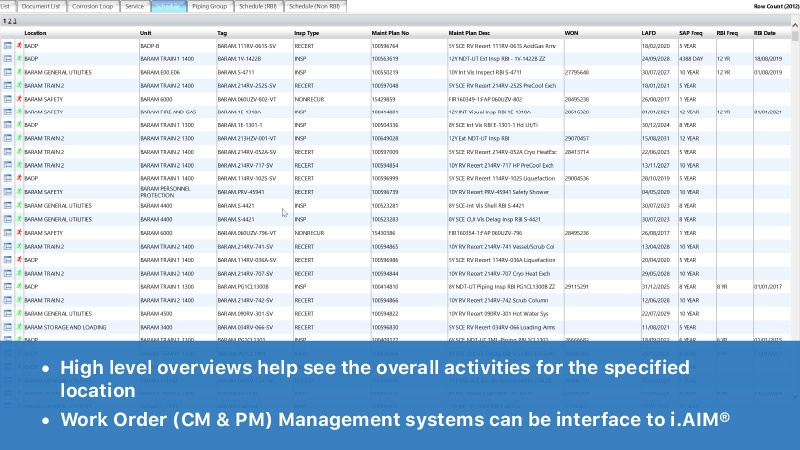

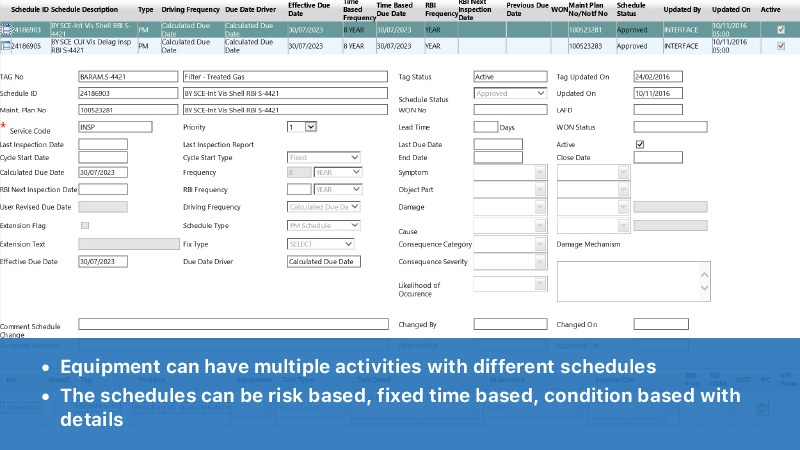

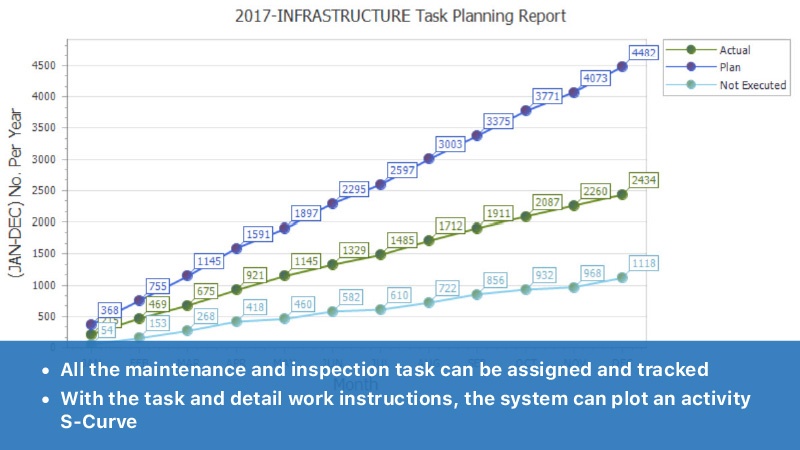

This module helps add a planning capability to asset integrity management. Typically, asset integrity management focuses on the technical aspect of the equipment, but that is not sufficient. Work/activities need to be carried out to collect the data, analyze the data, correct the issues, and complete work on time. As such, the work has to be organized and planned out. Without knowing the workload, issues pile up and the integrity status of the equipment that was once green will eventually become red when the work is delayed.

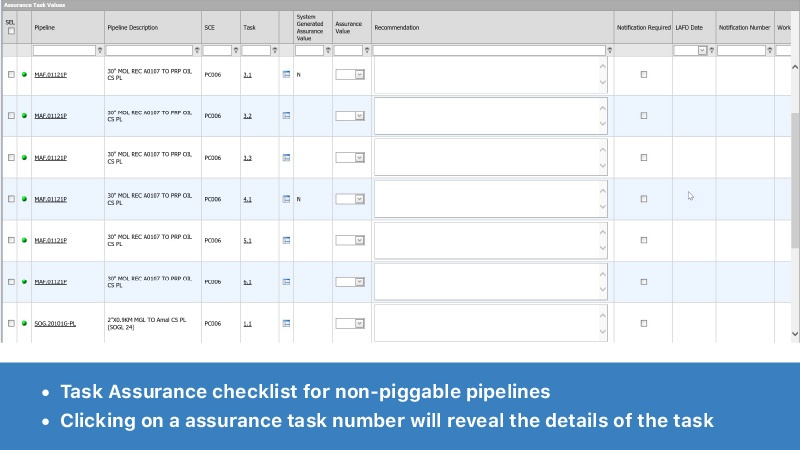

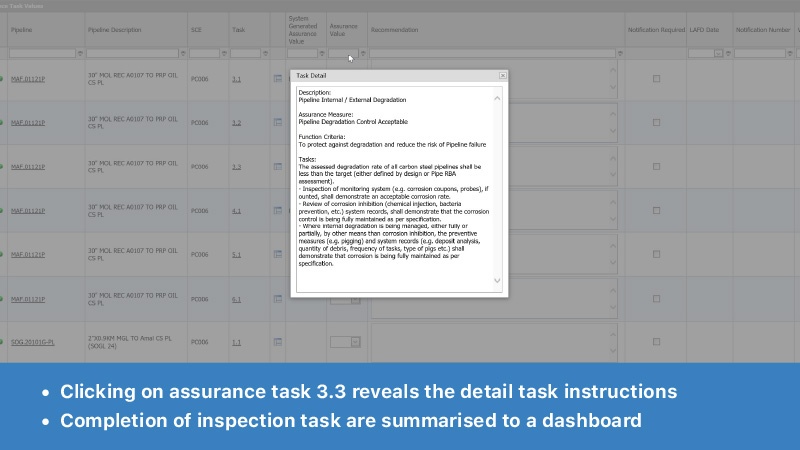

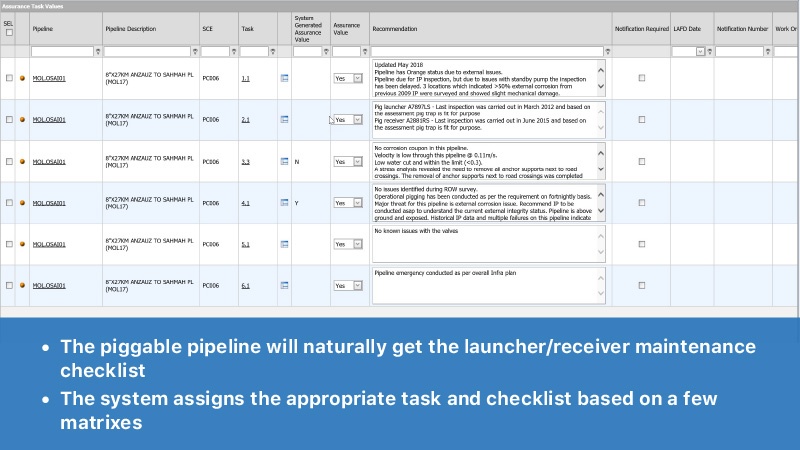

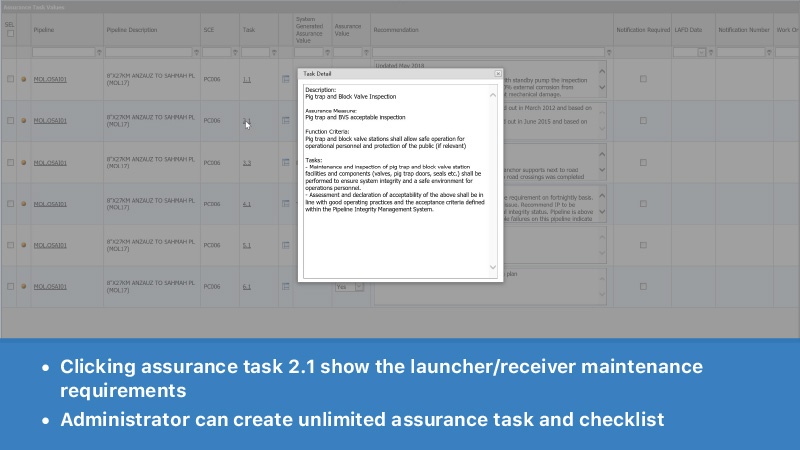

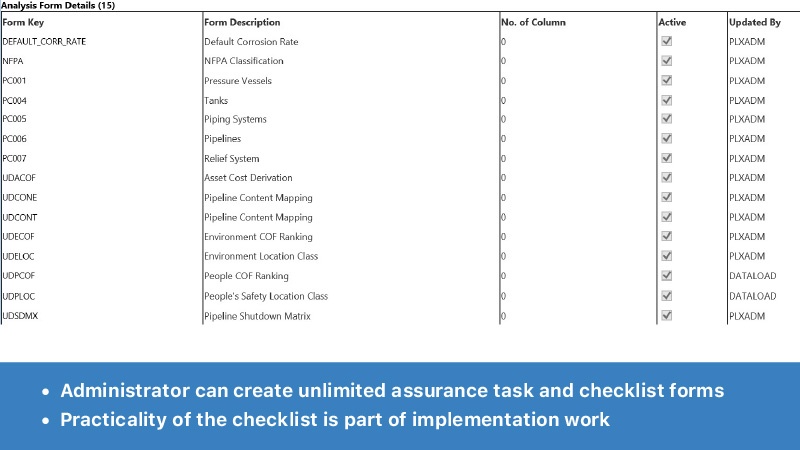

This is a specialized version of time-stamped checklist forms. There are checklists for piping integrity inspection, piping integrity assessment, different pipeline maintenance activities, storage tank inspection, etc. When the results are returned, i.AIM will summarize the results into a dashboard so a high-level overview can be seen. The checklist is also available on Android and iOS tablets, so field inspectors and maintenance teams can use it in the field. The checklist and all relevant documentation with drawings are downloaded into the tablet, so the team can have the required information to make the correct decision. Since it is downloaded, the team can work offsite at remote locations with no internet connection. Once an internet connection is available, the collected data can be synchronized with the main system.

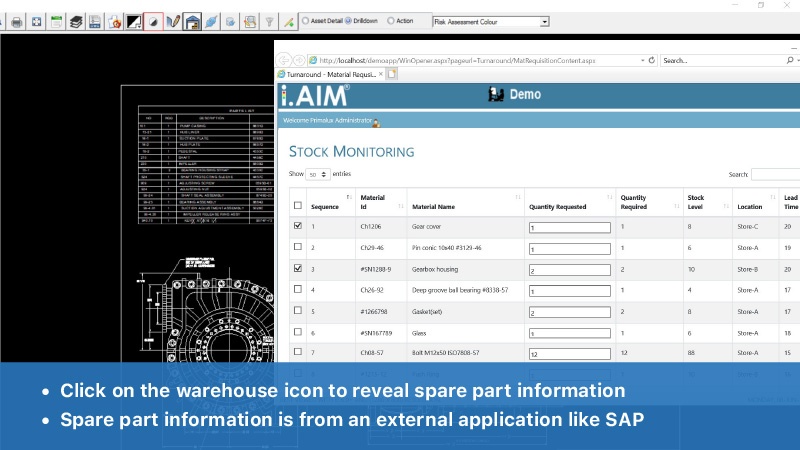

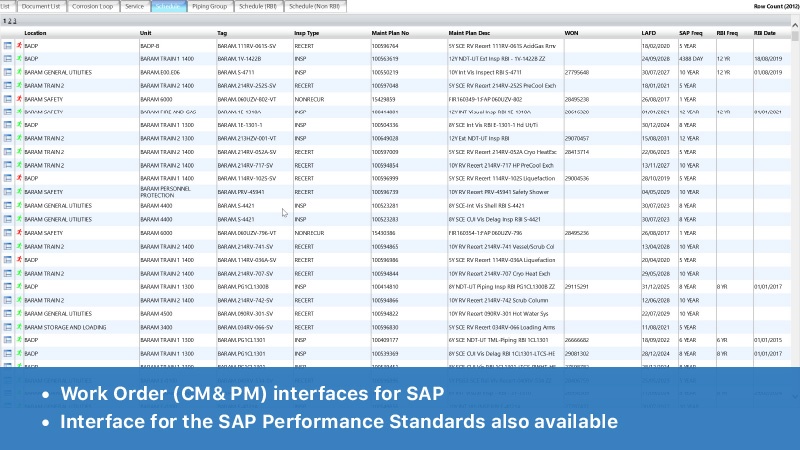

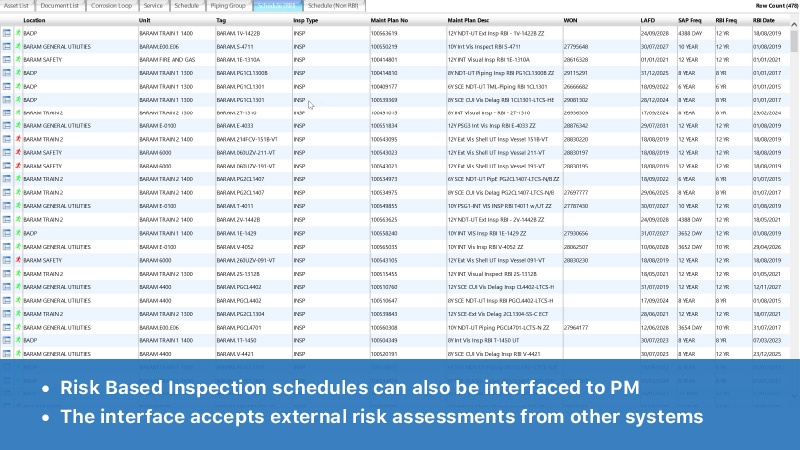

The company has many specialized systems to cater to the different aspects of production or activity management. Essential data reside in these external systems that can be used in i.AIM. Instead of re-keying the information into i.AIM or the external system, an interface can be used. Sometimes the interface is one way, sometimes it is two ways. This module maps external systems like SAP, PI, LIMS, ROSEN IPIG, AutoCAD, data loggers (Panametrics 36DL+ and 38DL+, etc.) into i.AIM. Once the mapping is known, along with the required timing or condition, and the site approval process is completed, data will be transferred as specified. Essentially, this is a hierarchy and data mapper between systems.

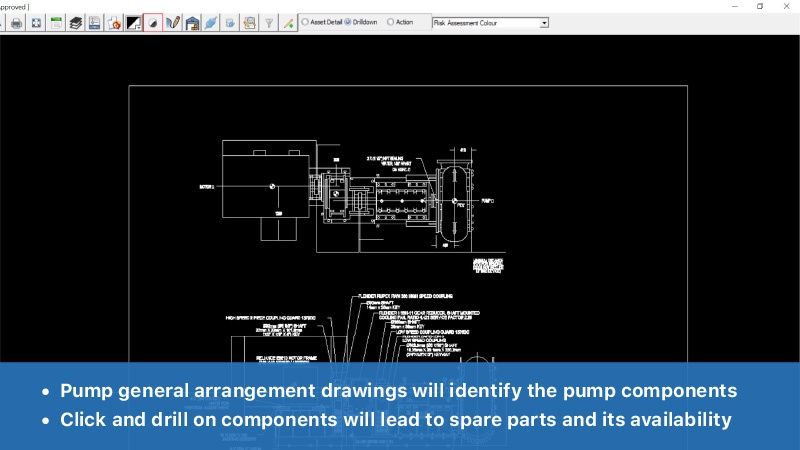

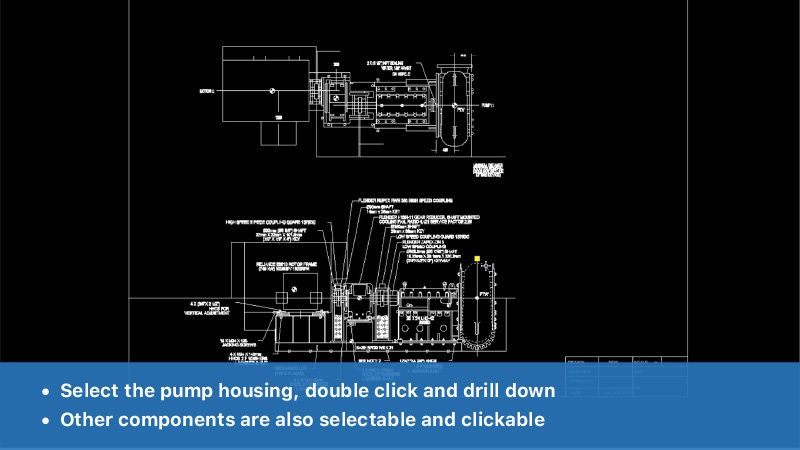

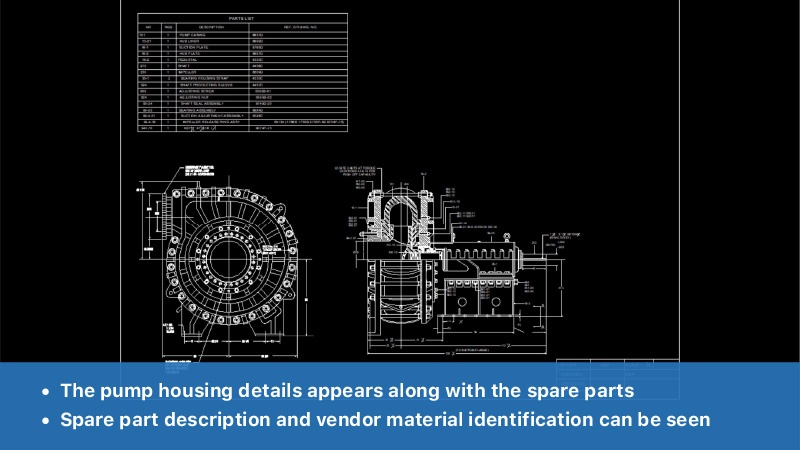

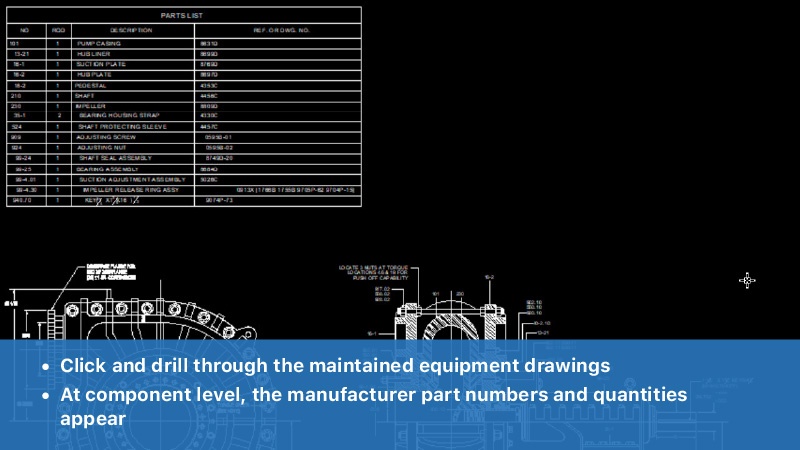

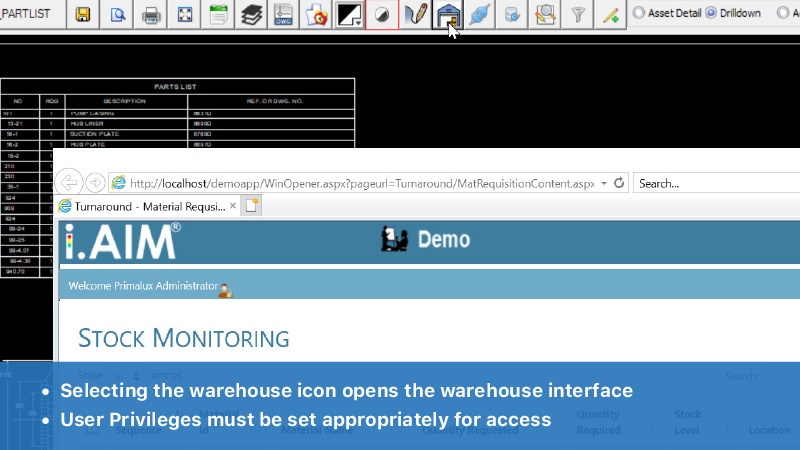

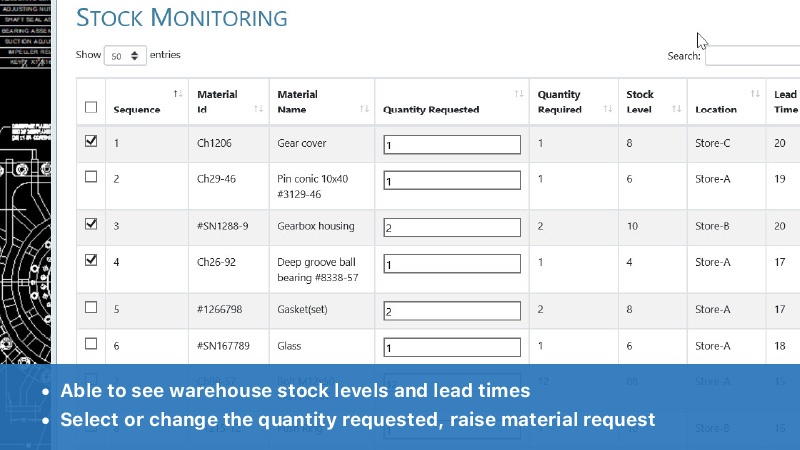

This is a specialized view of maintenance spare parts, and equipment drawings. With this module, the parts being ordered can be seen from the drawings, ensuring the correct parts are being ordered. Furthermore, with an interface to the maintenance warehouse management system, the available stock levels and lead times can be seen. Now, engineers can better plan their maintenance work, since the availability of parts can be seen alongside the specific part required in the form of a drawing (which is sourced from the respective equipment manufacturer).