Experience i.AIM®

A powerful asset integrity management system that easily integrates into corporate management and planning systems to ensure sustainable, safe and reliable production of your assets.

Do More with i.AIM®

Automate routine work and focus on what matters.

Maintain Assets

Register Anomalies

Assess Risks

Schedule Jobs

Create Work Packs

Plan Resources

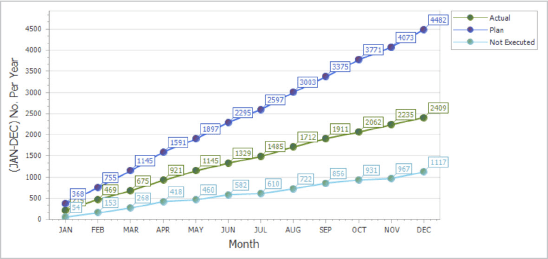

Monitor Execution

Report Integrity

Regenerate AIM Cycle

Oil and Gas

Paper Mills

Container Terminals

Chemical and Petrochemical

A suite of products to help customize your solution.

i.ENGINEER

Asset hierarchy and engineering, chemical, process specification forms.

Learn more >

i.DOCUMENT

Document and drawing registration with smart AutoCAD interface.

Learn more >

i.INSPECT

Equipment inspection management system.

Learn more >

i.RISK

Multiple decision matrixes specialized for risk management, for example Risk Based Inspection and Risk Based Assessment.

Learn more >

i.ANALYZE

Formulas that can be linked to forms, matrixes and data hierarchies. Used for equipment integrity assessments and roll up summaries or pass down calculations.

Learn more >

i.PLAN

Help package and plan activities, for example inspection planning and turnaround management.

Learn more >

i.COMPLY

Tracks quality assurance and compliance so decisions are based on reliable and on-time information.

Learn more >

i.INTERFACE

Interface to 3rd Party tools, for example SAP, PI, Rosen IPIG, Weatherford IPIG… many more corporate management and inspection tools.

Learn more >

i.STORE

Small spare part module for interfacing to corporate warehousing systems, ensuring correct and sufficient tools and materials for inspection and maintenance.

Learn more >

Breathe new life into your drawings.

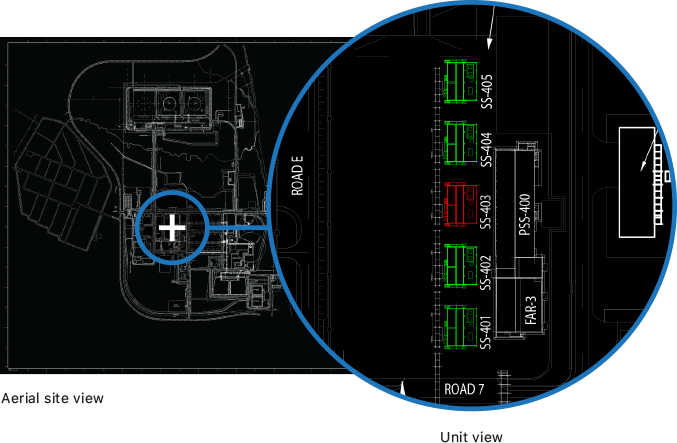

Universal Features

- Zoom in and out with multiple layers

- Traffic Light Colors KPI

- KPI relevant to drawing and user role

- KPI’s are configurable, so KPIs appear based on management direction

- Additional KPI’s can be customized

- Interface to SAP and PI

Universal Features

- Zoom in and out with multiple layers

- Traffic Light Colors KPI

- KPI relevant to drawing and user role

- KPI’s are configurable, so KPIs appear based on management direction

- Additional KPI’s can be customized

- Interface to SAP and PI

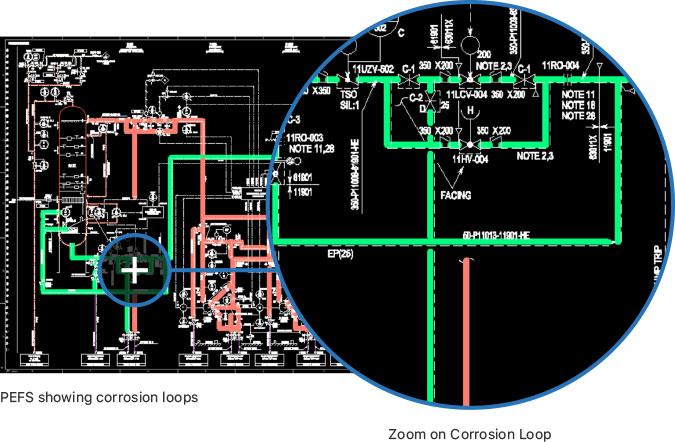

PFS / PEFS / P&ID

Example KPI’s on drawings:

- Traffic Light Integrity Status

- Traffic Light PM KPI

- Traffic Light CM KPI

- Previous Shutdown Scope Executed

- Current Shutdown Scope Planned

- Dynamic Corrosion Loops

- Visualized Dead Legs

- Corrosion Rates

- MTBF Rates

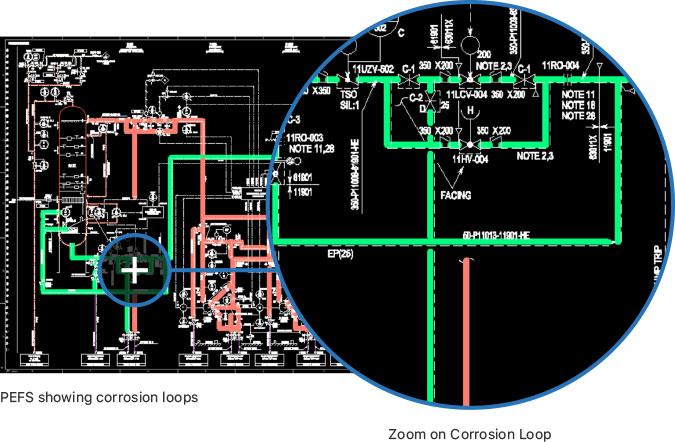

Isometrics

Example KPI’s on drawings:

- Traffic Light Integrity Status

- Previous Inspection Scope Executed

- Current Inspection Scope Planned

- Corrosion Rates

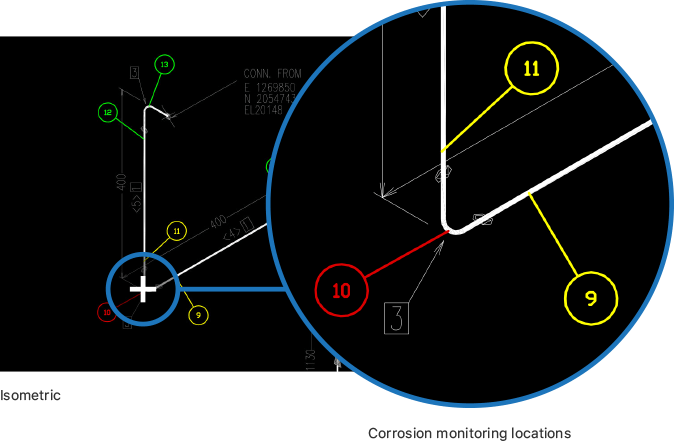

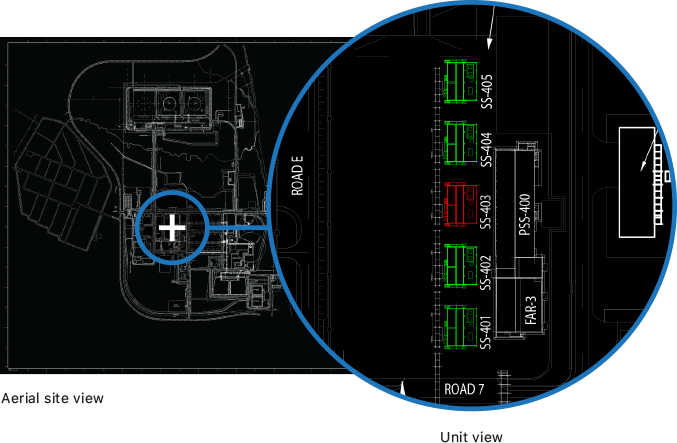

Plot Plans

Example KPI’s on drawings:

- Overview Traffic Light Integrity Status

- Overview Traffic Light Preventative Maintenance KPI

- Overview Traffic Light Corrective Maintenance KPI

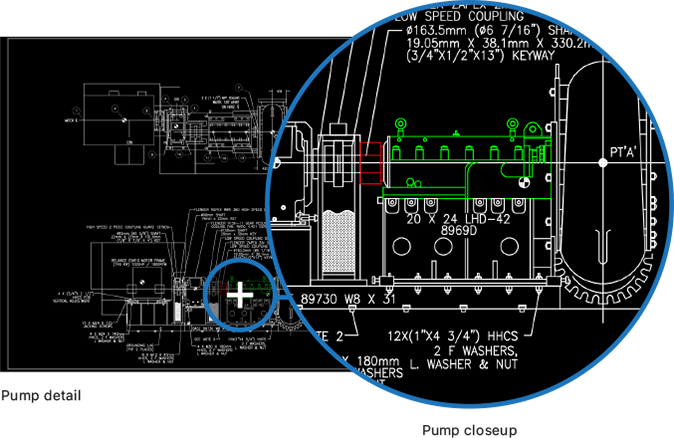

Equipment Details

Drill down data available:

- Traffic Light Integrity Status

- Warehouse Stock Levels

- Ordering Spare Parts

Additional Interfaces

Corrosion Module

Corrosion Management

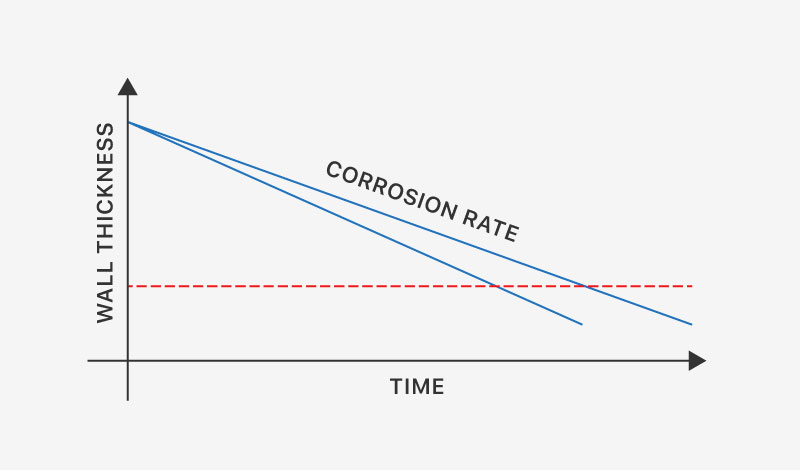

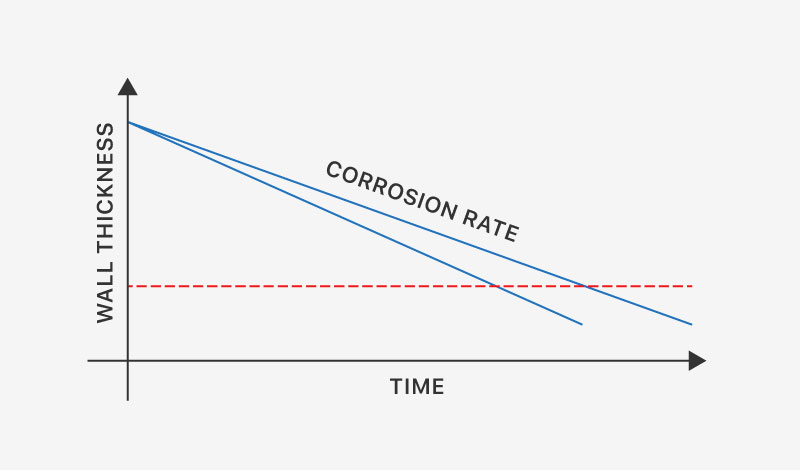

Corrosion Rate (CR) Assessment

- Corrosion Loop

- Equipment

- Piping

- Intelligent PIG

- Probe

- Coupon

- Theoretical

- External

- Sensitivity

- Overall

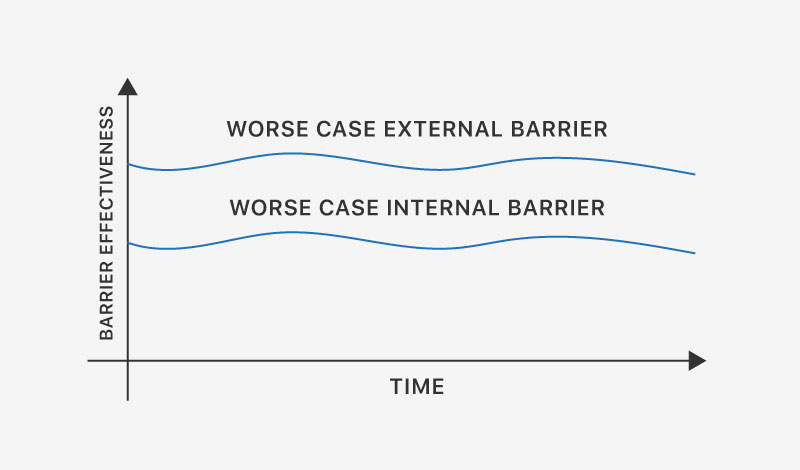

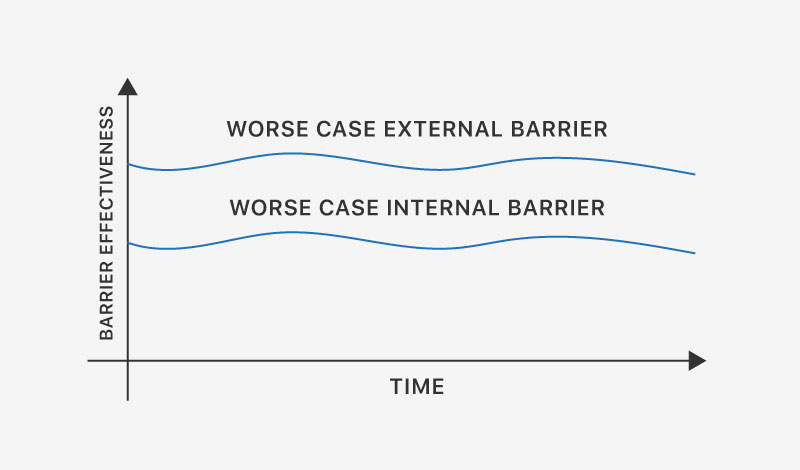

Corrosion Barrier Management

- Material Selection

- Corrosion Allowance (optional)

- Biocide Effectiveness

- Chemical Inhibition

- Cathodic Protection

- Work Order Interface

- Graphically display the status of the barriers on drawings

– Impressed Current

– Sacrificial Anode

– Monitor Preventative Maintenance

– Monitor Corrective Maintenance

– Raise Work Order Notifications

– Update PM Schedules

– Activity Status Updates

– Keep Engineers Informed

– Dynamic Corrosion Loops

– Highlight Pipelines

– Highlight Equipment

Integrity Operating Window Management

- Damage Mechanism

- Interfaces

- Graphic Integrity Operating Windows

– Tied to Corrosion Loops

– Tied to Pipelines

– Tied to Equipment

– Variables Monitoring

– Lab Information Management

– PI

– Work Order Management

– Dashboards

– Dynamic Drawings (Highlight Corrosion Loops, Pipelines, and Equipment)

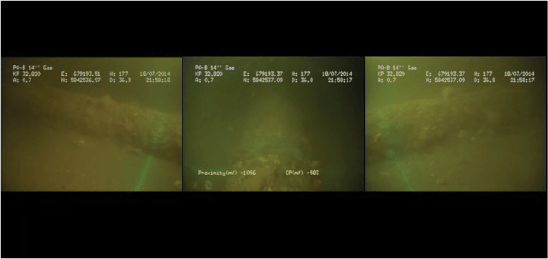

Tablet Module

Tablet Applications (iOS/Android)

Field Inspection

- General Visual Inspection

- UT Inspection

- Piping Inspection

- Equipment Inspection

- Structural Inspection

- Detailed Underwater Inspection (Tablet is not submersible)

Pipeline Field Data Collection

- Routine Pigging

- DCVG Data

- Venting

- Launcher/Receiver Maintenance

- Block Valve Maintenance

- Right of Way Inspection

- Near Shore Survey

- Earth Movement Survey

Seamless i.AIM® Interface

- Two-way Data Synchronization

- Works at Remote Sites

- Online and Offline Mode

- Downloaded Packages

- Reduces Reporting Latency

- High Data Availability

- Reduces Paperwork

- Onsite Data Validation

- Improves Data Accuracy

- Photos and Video Capturing

- Data Location Tagging

– Drawings

– Documents

– Photographs

– Work Packs

Tablet Benefits

Application for IOS and Android to perform field inspection allows the data synchronized back to the server to be fast and high quality. Work packs specific to the scope of work are created in the main system which include the forms, past issues, photos and relevant drawings. The application allows for offline mode which is useful when the work is being carried out in remote locations with no internet connection and is particularly useful when turnaround inspection requires fast and accurate reporting to help build the final turnaround scope. Benefits of tablet utilization include time savings, cost efficiency, seamless i.AIM interface, better data quality and portability/accessibility from anywhere.

Services

Services and support are available for the implementation and support of i.AIM® as well as the improvement of the Asset Integrity Management process for your company – ensuring maximum return on AIMS investment.